WATERFLO (OPTION):

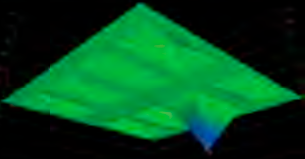

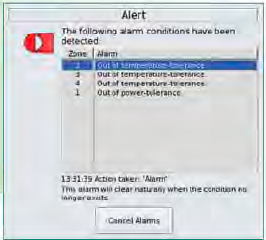

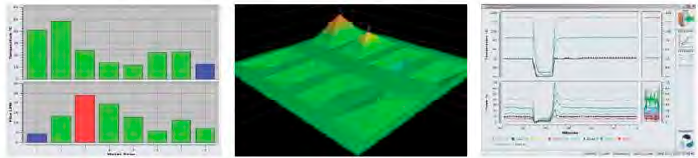

WaterFlo is an extremely powerful Real Time Water Flow Rate and Temperature Monitoring tool for a molds water cooling system. By incorporating it with our Hot Runner Control you achieve maximum production, quality and cost benefits. The Optional ITC Smart Manifold and WaterFlo Interface is an extremely accurate (1.5% full range) system, with the ability to Monitor, Measure and Graph fow rate and temperature on a real time basis as well as log 12 months of historical data for each cooling channel. this integrated package of actual water cooling and hot runner data allows for molding efficiencies hereto unavailable. Additionally a warning signal can be generated to activate and external warning device or even disable connected equipment. WaterFlo functions are integrated to display along side hot runner zones.